EQUIPMENT

After a flood, excess moisture can be difficult to deal with in areas between floors, within walls and in other voids. High-pressure vacuum drying technologies can be deployed to dry screed, under-screed and wall cavity insulation, dramatically reducing the amount of strip-out required. Our methods of high-pressure vacuum drying reduces drying times, disruption, costs and the volume of repair work required.

Our process begins by drilling a series of small, discreet holes into the area which needs to be dried. Hoses attached to the high-speed pressure drying system are then connected to the holes, enabling large quantities of heated air to be pressurized into the void.

Moisture-laden air within the void then heats up and evaporates through the holes we’ve drilled in the structure, ready for our dehumidifying technology to completely evacuate the moisture from the region. Should an even quicker drying process be required, our rapid drying technicians can seal all unnecessary openings in the room, and can even use tenting to create a controlled drying area and speed up the process even further.

At Humidity Response we thrive off using the most specialist equipment like Corroventa is the technology intensive company that combines the force of innovation with 30 years of experience within the field of water damage restoration.

Ideas are born out of the reality of our customers, often where accidents have occurred. Finding clever and efficient solutions that make our customers’ working days more efficient is a driving force for us.

Our products must work effectively and energy efficiently for many years. They have a robust design that can withstand rough handling in tough environments. In addition, it should have a long service life and be flexible enough for use in different conditions and assignments

Dedicated to providing the highest quality portable equipment, solutions and technical support for tackling environmental control challenges including restorative drying following floods or natural disasters and maintaining a healthy indoor environment.

Providing the best portable products for the restoration and maintenance of healthier indoor environments. Established in 1980 in Burlington, Wash, USA, Dri-Eaz developed the first commercial quality “snail-shell” air mover, which revolutionized the restoration industry.

Dri-Eaz has brought the restoration industry a number of other firsts, including inter-air drying systems and industry-specific moisture detection instruments. Today, Dri-Eaz manufactures a broad range of dehumidifiers, air movers, drying systems and air scrubbers used within water damage restoration, industrial drying, cleaning, and maintenance work.

We deploy the latest humidity technology combined with innovative

equipment to get your property back to normality as possible.

VELO AIR Mover

HEPA Air Scrubber

High Speed Air Mover

Small Dessicant Dehumidifier

Large Dehumidifier

Large Dessicant Dehumidifier

Large Low Grain Commercial Dehumidifier

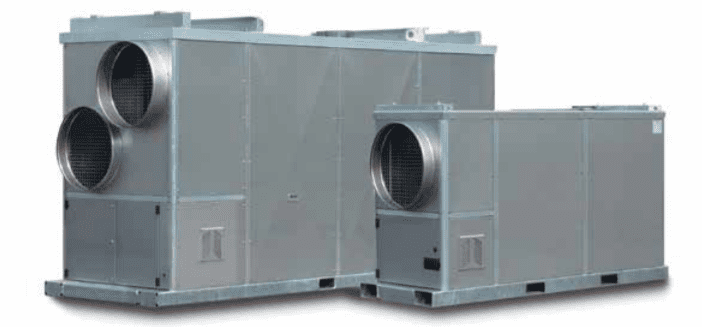

Commercial Dessican Dehumidifier

Head Office

Humidity Response Ltd

Unit 21

Bircholt Road

Parkwood Industrial Estate

Maidstone

Kent

ME15 9GQ

Calls may be recorded for training purposes

Contact us

Supporters of